One of the most important design elements in pneumatic conveying applications in the food industry is the cleanliness requirement. The equipment design, material usage, manufacture, installation, etc. must be considered for easy cleaning, cleaning and cleaning.

Materials should be placed to the maximum extent not allowed to residual bacteria led to breeding, where it can not be avoided to ensure easy cleaning.

Over the years continue to summarize the authority of the technology and key equipment testing and certification can fully meet the food industry's customer demand for material distribution security.

According to customer specific process needs and on-site conditions to provide targeted professional programs. From the unloading, storage, transportation, mixing, crushing, screening, in addition to foreign matter, drying, cooling, measurement and other aspects of consideration, and to the maximum consideration of the cleanliness requirements of the production process.

Material storage:

Whether tank car transport, or bagging raw materials. Through the installation of drying equipment, large storage tanks, small silos, feeding stations and other integrated solutions, both for easy transport unloading, but also in accordance with the raw materials required to control the temperature and humidity conditions.

Can also detect the amount of material stored online. Easy to use and stocking.

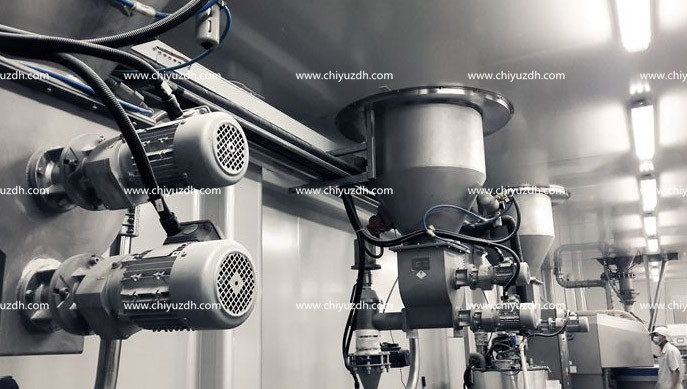

Material delivery:

According to the customer's specific site conditions, we provide a reasonable process configuration programs, flexible layout of the pipeline, can be carried out from a few points to a little or a little scattered to many parts of high-speed bulk materials transport.

We adopted the wind source cleaning technology, dual pigging technology and elbow special treatment in the pipeline processing, in the transportation process according to the characteristics of raw materials for iron removal, screening, grinding and other process operations; flexible use of different delivery methods , Effectively ensure the quality and safety of the material.

Powder, granules, liquid materials, storage, in the package, packet. Ingredients, excipients, trace materials, liquids and other automated production line weighing material; multi-recipe switching; various data reports; online real-time monitoring; material tolerance and other alarm error protection.

Accurate measurement, accurate time, clean environment, safe operation, perfect control function make the production flawless.